R+L Hydraulics GmbH presents couplings from the Spidex HighTemp and UltraTemp series, which have been specially developed for high-temperature applications. The flexible claw couplings are durable and resistant and are characterized by high temperature and hydrolysis resistance.

“Spidex flexible claw couplings offer reliable performance even under extreme conditions. They are the result of years of experience and continuous development,” says Detlef Peick, Business Development Manager at R+L Hydraulics. The exceptional temperature and hydrolysis resistance of the UltraTemp series enables it to be used at continuous operating temperatures of up to 180 °C – “a unique selling point in the industry”, says Peick. The three-part couplings are axially pluggable, fail-safe and maintenance-free, making them the ideal choice for demanding environments, for example in steelworks, lime kilns, drying plants and marine applications.

Thanks to the use of high-temperature resistant elastomer spiders, Spidex couplings are particularly durable and resistant to frequent temperature changes. This reduces downtimes and leads to longer maintenance intervals and higher system availability, which has both economic and ecological benefits. “The increased temperature resistance of our elastomer spiders makes it possible to use Spidex couplings reliably in processes with thermal processing steps,” explains Peick. “The ageing resistance of the HighTemp and UltraTemp spiders with frequent temperature changes contributes significantly to the longevity and reliability of the systems.”

Another advantage of Spidex couplings using UltraTemp spiders is their superior resistance to hydrolysis. This means that they can be used in humid environments, including seawater, and are therefore also suitable for marine applications and use in high humidity environments.

Depending on size and use, the couplings are designed for applications with up to 11,000 Nm nominal torque and a maximum torque of 22,000 Nm, which also makes them ideal for difficult tasks. “This superior performance, combined with excellent damping and the ability to compensate for high radial misalignment, sets new standards in the industry,” says Peick.

“R+L Hydraulics relies on transparent and comprehensible information on the temperature range in which the HighTemp and UltraTemp series can be used,” emphasizes Peick. “Some suppliers advertise with unclear information and the maximum temperature specifications are often misleading. Our customers can rest assured that our products reliably fulfill the promised properties.”

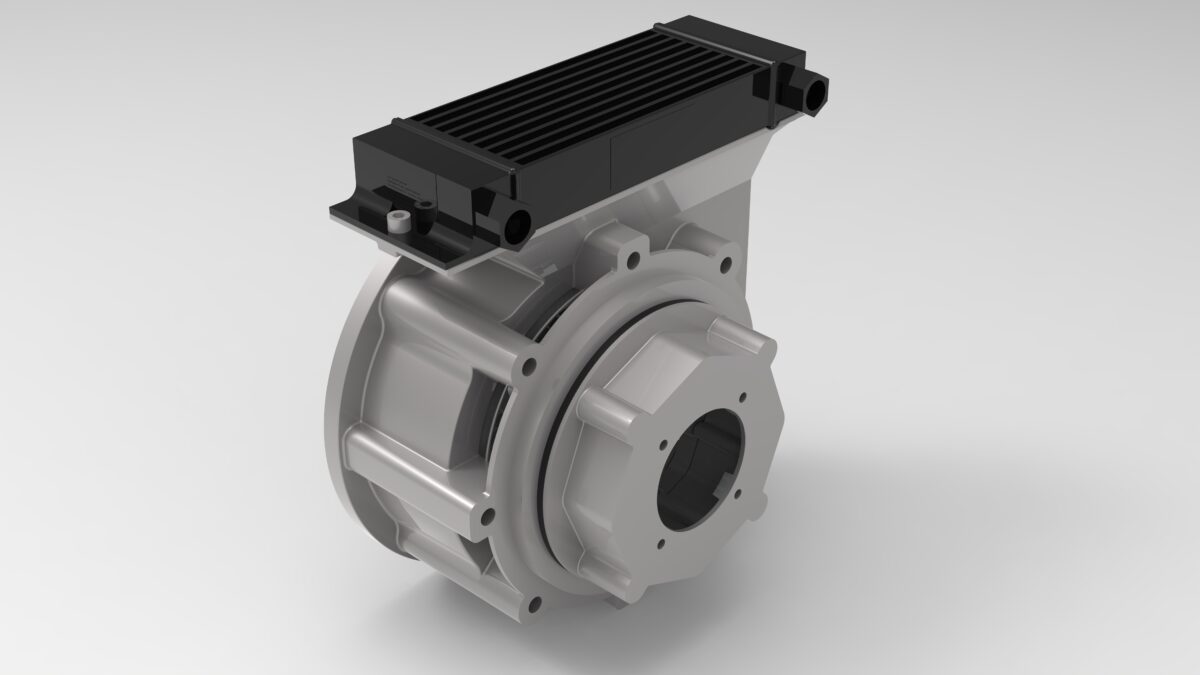

R+L Hydraulics, based in Werdohl in the Sauerland region of Germany, is a subsidiary of the US coupling specialist Lovejoy LLC; both companies are part of the Timken Company. In addition to Spidex couplings, R+L Hydraulics develops, produces and sells a wide range of components for fluid and drive technology, including other industrial couplings and hydraulic accessories such as bellhousings, damping elements, cooling bellhousings, heat exchangers, coolers and hydraulic tanks. The products are used in a wide variety of applications in mechanical engineering, shipbuilding and vehicle construction, energy and environmental technology, in the steel industry and offshore technology as well as in special plant engineering applications.

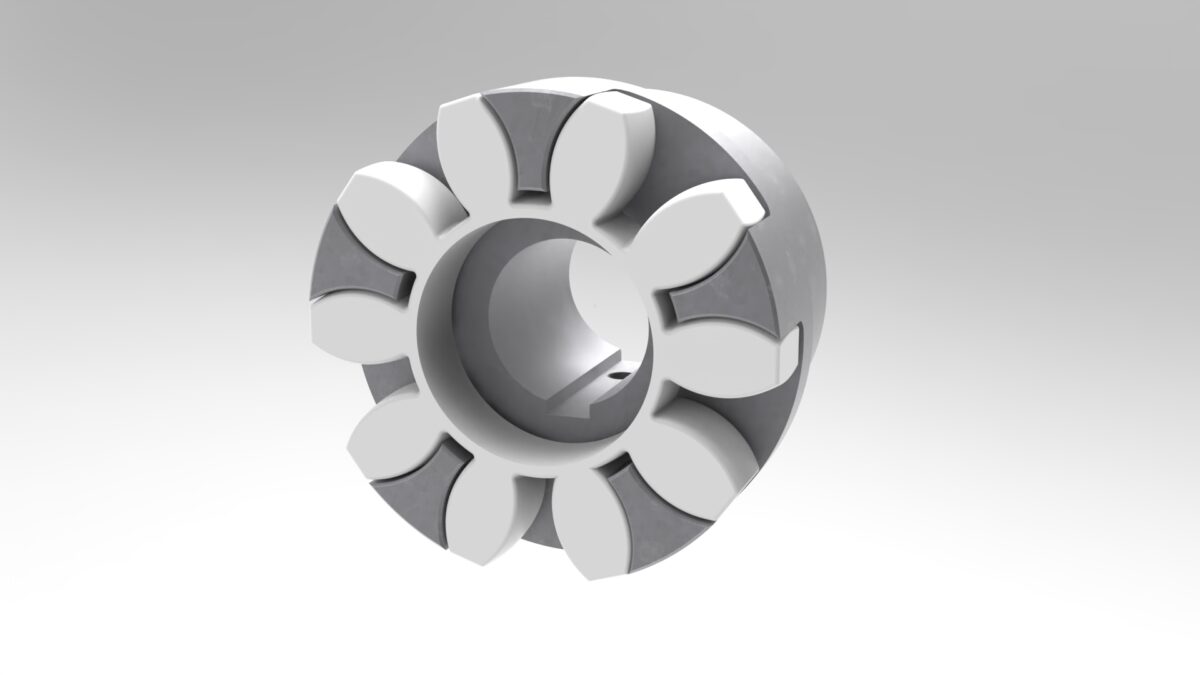

Picture:

View of a flexible claw coupling from the Spidex 100 series from R+L Hydraulics with white UltraTemp spider for high-temperature applications